With joined forces

B. Braun has been fighting against COVID-19, and for patients and medical professionals around the world since the start of the pandemic.

The second wave of coronavirus is here and it arrived even sooner than experts had expected: The number of coronavirus infections is now higher than ever. Many of our products are vital to the survival of people suffering from COVID-19. Here, we will show you how B. Braun has fought against the virus and for patients and medical professionals this year—and how we will continue to fight.

December 2019

+++ In the Wuhan province of China, a growing number of reports describe a new type of pneumonia that is more severe than the average. The official count at the end of December is 27 patients. +++

January 9, 2020

+++ After the WHO speculated that the disease is viral in origin, Chinese researchers are the first to identify the novel coronavirus. +++

January 24, 2020

+++ The first European cases of the disease appear in France. Two individuals are infected during a trip through China. A few days later, the first cluster of infections occurs in Germany at a Bavarian automotive supplier. +++

Something big is coming. Something that, in the coming months, will change the life of every person on the planet—however, only a few suspect it at this point. While the “novel coronavirus” has been appearing more and more in the news since the start of 2020, Wuhan—the location of the initial outbreak—is a long way from London, New York, or Rio de Janeiro. In Europe, everyone still feels safe. At B. Braun, however, the situation is already being taken quite seriously, since it is clear that if the virus spreads, the medical supplies that are already critical to the system will become even more important. On January 24, the company issues its first official statement about the coronavirus, sharing a tutorial on proper hand hygiene on LinkedIn: Spread the word—not the germs. The B. Braun subsidiary Aesculap Academy, which offers medical training around the world, switches to online courses in China, starting in February. Other countries follow suit. In the coming months, over 60,000 individuals around the globe will continue their education digitally.

Beginning of February 2020

+++ On February 11, the disease is given its official name: COVID-19, short for coronavirus disease 2019. In Germany, the hoarding starts. Above all, disinfectant becomes scarce, demand is 8.5 times higher than the year before. +++

B. Braun produces over 50 different germicidal products. Production at the Center of Excellence (CoE) for Infection Control in Sempach, Switzerland already runs at full capacity during normal times, which is why a new production facility is being built, which will be completed by 2022. “Virtually overnight, we were bombarded with inquiries—from all over Europe but primarily from Asian countries,” says Rolf Widmer, Head of Supply Chain Management in Switzerland. “We could’ve done three to five times our normal sales volume.” Production, however, can only be increased by about 30 percent, because preliminary products such as ethanol were almost unavailable.

“In this situation, we had to decide to make distribution as fair as possible. Even though we received unbelievable offers, we didn’t want to control sales using price,” explains Widmer. Instead, current customers were given first priority, they were promised at least as much disinfectant for 2020 as they had purchased in 2019. “We then focused on new customers from the German-speaking countries,” says Widmer.

More countries where B. Braun produces disinfectants

Beginning of March 2020

+++ On March 11, the WHO officially declares a pandemic. Infection and death rates in Europe rise quickly. Testing centers are set up in major German cities. On March 8, the federal government recommends canceling large events and encourages businesses to allow employees to work from home. Life as we know it changes. +++

At B. Braun, as many employees as possible are also working from home to prevent infections at the company. Within just two weeks, every location around the world switches to video meetings. This is a new situation for many employees—and something of an acid test, with colleagues facing a flood of customer inquiries while working at home. This is what happened at the Brazil location: In March, B. Braun received over 13,000 e-mails just at this location—an increase of nearly 50 percent. You do everything you can, though, to stay in touch with customers and partners during the pandemic, because communication is everything in a pandemic. The Communications department responds to this situation with the hashtag “#wearebusy—because our customers are”. In a large-scale campaign, employees report on their new daily routines working from home.

Inquiries to B. Braun Brazil that were handled from home

March 16, 2020

+++ All ICU beds in Germany are required to be reported using the German ICU Registry web portal. Elective surgeries that are not urgent are postponed to keep ICU beds available. +++

After seeing the photos from Italy and given the deteriorating situation in large parts of southern Europe, operations at German hospitals are completely overhauled, explains Dr. Michael Vogt, CEO of the German doctors’ association, Hartmannbund. “It then turned into massively slowing the increase in infection rates while also admitting as many ICU patients as possible.” Various means were used to achieve this. “Hospitals, of course, exercise the utmost care with regard to hygiene,” says Vogt. “Still, new standards had to be set. For example, some procedures were performed as though the patient had tested positive for corona.” Tending to patients in the isolation wards who are actually infected is particularly stressful for both doctors and nurses. “At the start of the pandemic, the lack of adequate protective equipment was a huge problem,” says Vogt.

B. Braun has many products in their portfolio that are designed to make working in a hospital better. Sometimes, all it takes is just a humble idea: self-adhering foam pads customized to prevent pressure on the skin under the weight of safety glasses and face masks.

The preparations for the wave of COVID-19 patients are demanding and require many hours of overtime from hospital staff. “But the German system has thoroughly proven itself so far,” says Vogt. At no time are ICU beds filled near capacity—even some patients from Italy and France can be treated.

March 22, 2020

+++ Italy and Spain are under lockdown. Even in Germany, the federal government and the states agree on comprehensive contact restrictions to stop the spread of the virus. +++

The lockdown hits everyone hard. The measures are particularly drastic for people who depend on dialysis. These patients must leave the house and visit a renal care center as often as three times a week in cases with total renal activity replacement. And because the average age of these patients is just over 60 and some have multiple severe comorbidities, they belong to a risk group. In Germany, 0.3 percent of those who get COVID-19 die from it; for infected dialysis patients, this figure is 20 percent.

After the start of the pandemic, it immediately becomes clear to the B. Braun team in Melsungen who coordinate the work of renal care centers in 30 countries that everything needs to be done to protect patients and employees. “We immediately activated our global pandemic plan, in which the specific preventive measures for every center are described in detail and implemented accordingly,” says Martin Meier, manager of Global Provider Operations. By and large, it involves the overall recording of all measures necessary during the pandemic, including hygiene, training, communication, behavior patterns, and emergency protective equipment supply. Everyone who enters the renal care centers has their temperature taken and they are asked about any health conditions.

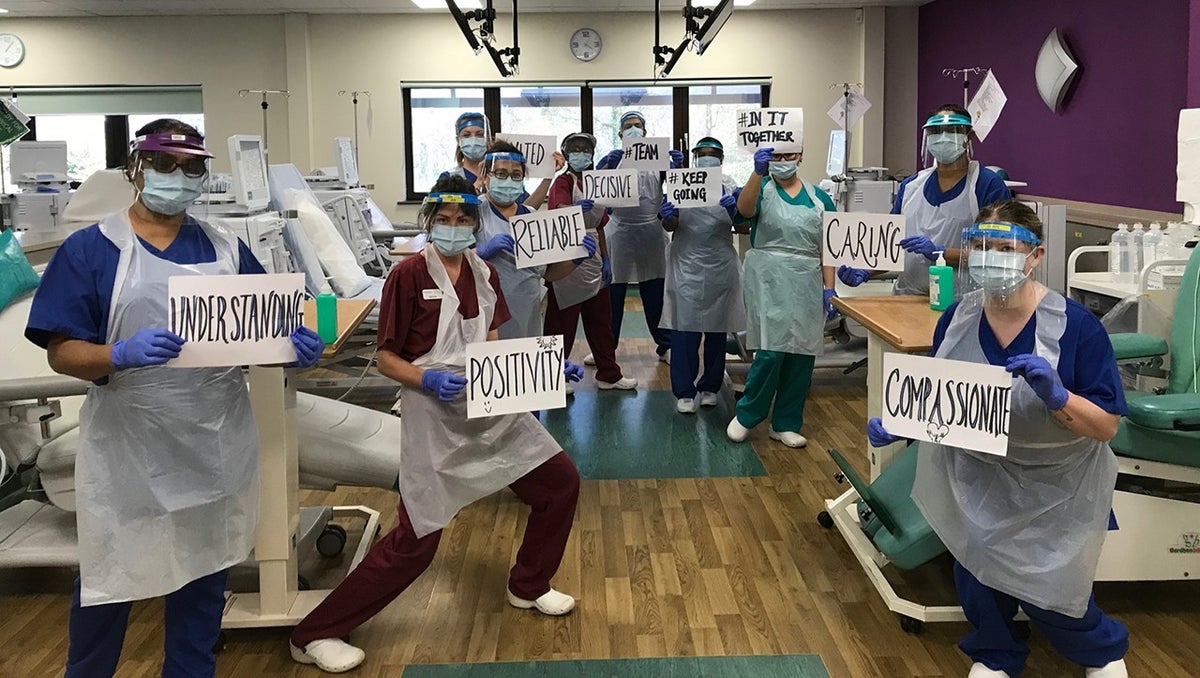

The pandemic also effects the routine processes inside the center, says Meier. “During weighing before and after dialysis, for example, sometimes lines form, that now needs to be prevented. The employees constantly need to be on alert to monitor the patients.” One serious challenge for the centers is staff shortages. “As soon as an employee starts showing symptoms of the disease, they’re tested,” says Meier. “Until the result comes back, however, they need to be in quarantine. This is why the schedule needs to be rewritten so often. We’re proud of our employees who kept things going at these centers and gave everything they could under difficult circumstances.”

Patients at B. Braun renal care centers around the world, 2015–2019

March 28, 2020

+++ More than 750,000 people have been infected with the novel coronavirus worldwide. At its peak, Germany reports more than 6,000 new infections in a single day. German doctors’ association the Marburgerbund expresses concern over a dangerous lack of medical-grade face masks in Germany. +++

Even a wealthy and technologically advanced country like Germany has serious trouble providing an adequate supply of personal protective equipment during the pandemic. Together with logistics services provider DB Schenker and Lufthansa Cargo, B. Braun transports 2.8 million medical-grade face masks from China to Germany. An Airbus A330 was chartered to do this—a passenger airliner. The seats and even the overhead storage compartments were packed to stow about 6,000 boxes. After landing, the masks are distributed to hospitals throughout Germany—around 450,000 are used at B. Braun facilities.

Beginning of April 2020

+++ The situation in Lombardy in northern Italy escalates. Several hundred people succumb to COVID-19 every day. +++

The world looks on in horror as Bergamo stacks caskets in temporary cold storage facilities and has them carted off on military trucks. Hospitals don’t have enough ICU beds. Doctors need to decide who has the best chance of survival—and who does not. The problem is: The number of ICU beds cannot be increased quickly, since they are complex systems that use numerous pieces of lifesaving equipment. When crucial medical technology is missing, the ICU bed is unusable.

At the heart of this combination are the infusion pumps, through which medications such as anesthetics and life-saving drugs are administered. At B. Braun, this segment has been growing for years. “Normally, our growth is up to ten percent per year,” says Marco Lorenz, Vice President of Marketing and Sales for Automated Infusion Systems. “Our experience with past pandemics is what gave us in inkling that something really big was headed our way back in February. Starting in the second week of March, the number of orders doubled every two days and within two weeks, it reached ten times that of an entire month. That’s almost our entire normal annual volume.” B. Braun is unable to meet this demand in the short term or cover the usual delivery deadlines.

The company works feverishly to increase production. Manfred Herres, senior vice president of the CoE for Active Medical Devices, runs B. Braun Avitum’s plants in Melsungen, where infusion systems, and the acute dialysis machines that are just as vital to many ICU patients survival, are manufactured. “Normally we work two shifts, five days a week, but then we switched to three shifts, seven days a week—in other words, ‘round-the-clock production. All our resources were used, even the training center.” In the second and third quarter, this leads to a production increase of 100 percent, or 60 percent across the entire year.

Nevertheless, the problem of which hospitals receive these scarce goods must be solved. B. Braun formed a six-person crisis team that meets daily and attempts to prioritize the demand from global markets and customers. “That was an unbelievably complex task, the variables changed every day,” says Lorenz. “We gave the team total decision-making authority.” Especially at the beginning of the crisis, hospitals with acute needs received more equipment than those that were stocking up simply as a precaution. Still, Lorenz concedes, “In this situation, it’s difficult to make the right decisions, since someone will always be disappointed in the beginning. However, in the eyes of the vast majority of our customers, B. Braun was able to provide a very good service and high supply availability during the crisis.”

May 11, 2020

+++ Coronavirus emergency clinic opens in Berlin. +++

Within just six weeks, an emergency clinic is set up in a hall at the Berlin Messe trade show center to relieve pressure from other hospitals as needed. The facility can hold up to 500 ICU patients. B. Braun helps with the medical facilities—primarily by supplying critical infusion pumps. Since its opening, the clinic has been in standby mode. It has yet to treat any patients but can take them in at any time.

June 2020

+++ In Germany, a coronavirus warning app is launched and downloaded by millions. In Europe, the situation has relaxed a little. In the Americas, however, the situation continues to worsen. +++

July 2020

+++ New infections in Europe decrease steadily, hospitals switch back to normal operations. The backlog of surgeries is worked out. +++

The pandemic has countless impacts on the healthcare system. Some, such as the increased need for ICU beds, are foreseeable. Others are surprising, such as the new demand for a device called an insufflator, which can reduce the spread of deadly viruses in the operating room. This device is used during laparoscopy, a surgical procedure that utilizes small incisions made in the abdomen to insert a camera and surgical instruments. In order for surgeons to even be able to work, however, they need room to operate. This is where the insufflator comes in: a device that pumps CO2 into the abdominal cavity using a tube. These types of minimally invasive procedures have been increasing for years and have become standard for gall bladder and intestinal surgery. The surgeons usually work with high-frequency electrical surgical instruments that use current to cut tissue and cauterize blood vessels. This produces something called surgical smoke, which the insufflator can evacuate through a second tube.

How the insufflator makes operations in corona times safer

Marco Metzger, a junior product manager at B. Braun, is responsible for the insufflator. As he explains, “The insufflator's pumping function is essential. Without it, you can’t perform the surgery. Whereas extracting the surgical smoke is optional, though sometimes it's necessary to improve visibility in the abdomen. The surgical smoke has an unpleasant odor and is potentially cancerous. For example, in Scandinavian countries, surgical smoke evacuation is mandatory. In other countries, though, it's sometimes considered practical but unnecessary.” Then came the pandemic—and with it, surgeries also needed to be made even safer.

The question arose, can corona viruses be emitted from the patient’s body in the surgical smoke, making it a potential route for virus transmission? By using a filter, surgical smoke evacuation can prevent a very high percentage of the probability of transmission via surgical smoke. “Since the start of the pandemic, we've observed that the demand for products involving evacuation in particular has grown sharply—sales of disposable tubes rose by around 69 percent,” reports Metzger. “This is good for us, but ultimately the surgeons and OR staff benefit from procedures being easier and safer as a result.”

November 2020

+++ The number of new infections in Germany skyrockets again. The German cabinet enacts a less restrictive lockdown. The situation in other European countries is also deteriorating. +++

For a few months, it looked as though countries such as Spain, France, and Germany had COVID-19 under control. While countries such as the United States or Brazil were reporting tens of thousands of new infections every day, the wave of infections in many places in Europe flattened out. But the dust has yet to settle. Since the end of August, infection rates have risen again; in Octo-ber, Germany passed the psychologically critical 10,000 daily new infections mark—far more than in April. In November, the German cabinet imposed a "lockdown light” in an attempt to reduce infections while keeping schools, gov-ernment offices, and a majority of businesses open. France has been forced to take more drastic measures, with public life completely shut down for one month.

However, as Dr. Michael Vogt from the Hartmannbund German doctors’ asso-ciation also points out, “Germany is one of the countries that, so far, has man-aged this historic crisis the best.” According to Dr. Vogt, the pandemic has shown that a modern, well-equipped health care system is not a luxury, it con-tributes decisively to the safety of the population. There are six ICU beds per one thousand inhabitants in Germany—in Italy or even the United States, there are only around two and a half. “Options like in China, where entire districts were cordoned off with barbed wire, are fortunately out of the question in this country,” says Dr. Vogt. “So, it’s about taking moderate, balanced steps to ensure that the health care system isn't overloaded.” Time will tell if these are sufficient.

At B. Braun, everyone is fully cognizant of this stressful situation. For now, it looks as though there will be no time for a breather. “In the last few months, though, we've proven that we can respond quickly when under pressure,” says Manfred Herres, head of the B. Braun Avitum plants in Melsungen. “For now, we’re going to continue production at a high volume.” Herres is especially proud of the employees at B. Braun. “Absences, such as from illness, have been lower than ever in the past months. Everyone here understands: Every hour worked here, every device that leaves our plant helps a person somewhere in the world.”

B. Braun thanks all employees for their dedication during this coronavirus crisis. The company hopes that you, the reader, stay healthy and are able ride out this time both professionally and privately.